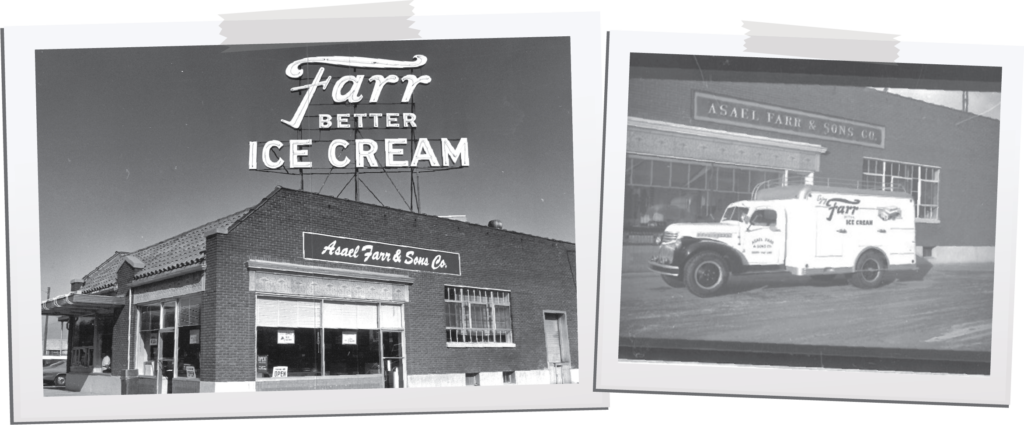

On March 25, 1920 Asael and his children incorporated the family business under the laws of the state of Utah and named the company simply; Asael Farr & Sons Company.

Dexter purchased a new home for his expanding family, moving from a small stucco house on Liberty Avenue to a large, $10,000, all brick, 13 room home featuring a two-car garage on Marilyn Drive in Ogden. In doing so, Dexter realized that Asael Farr & Sons Company would not be able to keep up with the economic demands of six growing families. He decided the best strategy for the family business would be to expand into ice cream manufacturing and retailing. He had discovered that commercial ice plants had a strategic advantage when expanding into ice cream manufacturing. Dexter began lobbying his siblings and father to invest in an ice cream plant. Eventually, his efforts were successful.

In 1929, the components of an ice cream plant were purchased. New construction on the red brick ice plant costing $5,000 added to it, 1/3 of the building as it stands today, which included an ice cream manufacturing plant and ice cream parlor. The new ice cream manufacturing equipment was installed, including two, 10-gallon batch freezers for a total capacity of 20 gallons per hour.

The new ice cream plant began producing vanilla, chocolate and strawberry ice cream flavors and then shortly thereafter six or seven additional fruit and nut flavors were added. A heaping scoop of ice cream was sold for a nickel in an ice cream parlor adjacent to the plant. Word spread quickly about the delicious ice cream available from the new ice cream plant in downtown Ogden. Crowds began gathering, almost from the parlor’s inception, clamoring for the soon-to-become famous ice cream. Then suddenly, and unexpectedly, just weeks after opening the ice cream operations, on October 24, 1929 the US stock market crashed triggering the 11 year Great Depression.

Discouragement settled upon Ogden, just as it did throughout the country. Yet, timing for Farr’s new ice cream could not have been better. Farr’s Ice Cream provided a cheap and relatively affordable diversion from the gloom of the Great Depression. A mere nickel could raise the spirits of men, women and children as folks grappled with the challenges of life. Although other ice cream shops had opened throughout Ogden, including notably Brown’s and Paramount, customers reasoned that somehow Farr’s Ice Cream was just better than the other brands. So many customers insisted that Farr’s was better, that soon the expression, “Farr Better Ice Cream” was coined and has become a slogan recognized throughout the western United States for almost a century.

The ice cream division of Asael Farr & Sons Company was successful right from its start. With so much demand on him, Dexter needed help in the manufacturing plant. He turned to a close friend and fishing buddy Von Allred, who also happened to have a Dairy Science Degree from Utah State University and recruited him to become the ice cream plant manager. Von eagerly agreed and hired his wife Lola to assist him. Over the next couple of decades, Von and Lola developed over 600 different ice cream flavor recipes, many of which are still used to this day.

The 1930’s, 40’s and even to some extent the 1950’s were a time when ice cream was primarily purchased from ice cream parlors or shops, as the grocery trade was slow to embrace the frozen food industry. During these decades, Farr Better Ice Cream sought to reach the public through a growing number of company owned ice cream shops. A Farr Better Ice Cream Shop opened at the northeast corner of Harrison Boulevard and 24th Street in Ogden. Then a third shop opened at about 38th Street and Washington Boulevard as well as a shop and wholesale depot in the 700 east block of South Temple Street in Salt Lake City.

In 1956, Dexter recruited his son, Dexter Duane, recently graduated from Utah State University, to join the business. Though doing so was not Dexter Duane’s plan he could see that his father was shorthanded and felt as if he could be of some help. Dexter Duane was assigned to work in every position in the ice cream business, except as a pasteurizer as that position required a state license. Dexter Duane was then appointed as Sales Manager for the company. At that time the business had one, 150 gallon per hour continuous ice cream freezer and the two original 10 gallon per hour batch freezers providing a maximum capacity of 170 gallons per hour. In addition to its company owned shops, by 1956 Farr Better Ice Cream was also sold to 139 wholesale customers consisting mostly of grocery stores and restaurants.

Dexter Duane’s affable personality and passion about the family’s brand combined to steadily grow Farr Better Ice Cream. One of the more memorable marketing efforts he orchestrated included an advertising campaign featuring The Quality Kid. In the 1950’s and 60’s “cowboy westerns” on television and at movie theaters reached their zenith. From Daniel Boone coonskin hats, to The Rifleman’s toy rifles, not only adults, but also children were enamored with wild west heroes. Capitalizing upon the popularity of western cowboy themes, Dexter Duane imagined an ice cream cone comic strip-type character, donning a ten gallon cowboy hat and western bandana, who would espouse the positive features of Farr Better Ice Cream and be affectionately known as The Quality Kid. Such a character, Dexter Duane believed, could become the company spokesperson and be featured not only in the newspapers of the day, but also on posters and signs in grocery stores and billboards along roadways.

Although, Dexter Duane could imagine The Quality Kid, he was not a commercial artist and could not actually bring The Quality Kid to life. So, he turned to a local commercial artist by the name of Burke Mattsson, whom he commissioned to not only create The Quality Kid character, but to also use Dexter Duane’s concepts for advertising messages in newspaper serial ads. Together, Dexter Duane would suggest the content and message of the ad and Burke would draw the delightfully charming and often amusing comic strip type advertisements. These iconic, 1960’s style ads ran in newspapers in northern Utah and southern Idaho including the Ogden Standard Examiner and Idaho State Journal. The Quality Kid, and the insights about the fine qualities of Farr Better Ice Cream which he would share with other characters in his vintage comic strip world, became a unique and well recognized advertising effort further endearing consumers to Farr Better Ice Cream.

Eventually, The Quality Kid’s creator, Burke Mattsson made his way to southern California where he became a Disney artist and worked on such classic Disney movies as The Jungle Book, Thumbelina, The Lion King, Beauty and the Beast, Aladdin and dozens of additional movies. But, members of the Farr family, who from time-to-time stumble upon old Quality Kid ads in the company’s archives, gently smile as they realize that as great as some Disney classic movies are, they may not have been so great, if not for The Quality Kid and the opportunity it provided for a young, Ogden artist to make good in Hollywood.